Laser Marking Application

In Laser Marking, a laser beam is used to make permanent marks on materials such as glass, various types of plastics and polymers, gold, sliver, stainless steel, aluminum, anodized aluminum, copper, brass, other metal alloys, ceramic etc. The marking content includes texts, logos, different shapes, graphics, patterns, bar-codes and 2D matrix-es. Some areas that will affect the marking result include the type of laser used, the parameter settings as well as the material itself.

Typical laser marking effects include:

- Melting the surface

- Scorching

- Removal of the surface layer

- Oxidization of the surface

- Engraving

- Change of color

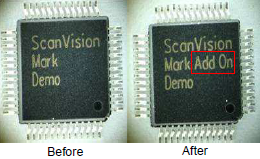

Result of Laser Add On Marking

The material plays a very important role in the result achievable. Variations in the material composition, and even different color pigments in the same type of material can result in very different marks. Laser Marking is by far the largest single application for lasers in industry. The use of lasers in marking is becoming widespread even replacing the inkjet markers which requires relatively expensive ink cartridge replacements. The clean environment in laser marking applications is also one advantage that industry is moving towards. Hylax offers a wide range of laser marking systems to cater to different applications, including marking on ICs, keypads, keyboard, PCBs, flex circuit, security tag, watch back cover, surgical tools, tools, wafer, ID card, jewellery, connectors, lens etc.